Carbon Brush

CD Graphite Company’s carbon brush is widely used in railway, metallurgy, nenergy, building materials, machinery manufacturing, automobile transportation and other fields of national economy.

- Railway locomotive carbon brush

- Industrial water conservancy carbon brush

- Wind electric carbon brush

- Micro type carbon brush

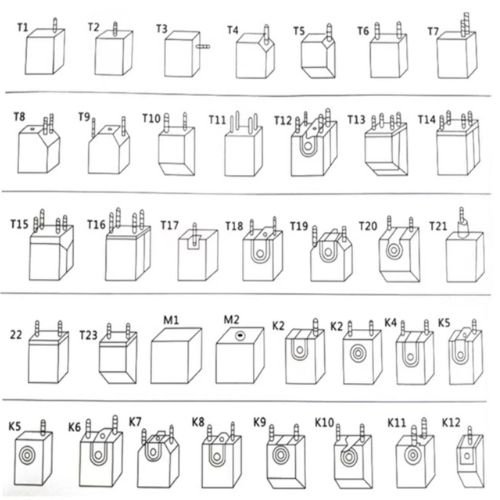

The structural form of carbon brush(the outlet wire method of carbon brush)

T type and K type are common patterns according to the wire assembly method. We also have M type and H type if you need.

Some Kinds of Our Carbon Brushes

Carbon brushes, also known as electrical brushes, are a type of sliding contact widely used in many electrical devices. They are used on the commutators or slip rings of motors as sliding contacts for drawing and introducing current. They have excellent electrical conductivity, thermal conductivity and lubrication properties, and possess certain mechanical strength and reversible sparking characteristics. Almost all motors use carbon brushes, which are an important component of motors. They are widely applied in various AC/DC generators, synchronous motors, battery DC motors, crane motor collector rings, various welding machines and so on. The main component of carbon brushes is carbon, which is prone to wear. Regular maintenance and replacement should be carried out, and accumulated carbon should be removed.

Applications

Carbon Brush Pressing Workshop

Machine Thread Filling for Carbon Brush

The frequency of carbon brush replacement for generators is not specified. It is necessary to determine the frequency of replacement according to various factors such as the hardness of the carbon brush itself and the frequency of use. If used regularly, it will be replaced in a year or so. A carbon brush is an easily worn product, and its wear is difficult to perceive. Generators need to be disassembled for inspection, so the carbon brushes need to be maitained. The carbon brush can reach 2000 hours under good commutation conditions, but may only reach 1000 hours under extreme conditions, and the service life can generally reach 1000h-3000 h.

If the starter carbon brush is broken, the car cannot be started. It will be a “da” a sound, then there is no response or it needs to start several times before it starts.

The material of starting motor carbon brush is mainly composed of graphite containing copper and silver, which is to increase electrical conductivity, and the texture is soft and wear-resistant. The shape is square block, and in the starter, the spring preload force is compressed on the commutator shaft of the starter.

Motor carbon brush is an important part of the motor, its main role is to transfer current, to achieve the normal operation of the motor. In order to ensure the normal operation of the motor and extend the life of the motor, we need to pay attention to the following matters and carry out correct maintenance.

First of all, pay attention to avoid overload when using it. Overload work will lead to increased wear of motor carbon brush and shorten its life.

Secondly, it is important to maintain good contact between the motor carbon brush and the motor rotor. Check the motor carbon brush regularly to ensure that the surface of the carbon brush is smooth and no cracks. When replacing the carbon brush, pay attention to the selection of the same model specification as the original carbon brush to ensure that the normal conduction of current.

In addition, it is also important to keep the inside of the motor clean. If there is dust and impurities inside the motor, it will affect the normal operation of the motor, and even lead to increased wear of the carbon brush.

Finally, frequent start and stop should be avoided during the use of the motor. Frequent start and stop will cause the motor carbon brush to be impacted and accelerate wear.