Carbon Carbon Composite Material Aircraft Brake Discs

- Low density

- High strength

- High specific modulus

- High temperature resistance

- Low expansion coefficient

- Good friction performance

What is Carbon Carbon Composites?

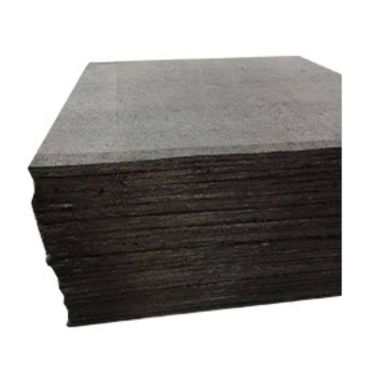

Carbon carbon composite materials refer to all-carbon composite materials made of carbon fiber and its fabric as reinforcement materials, carbon or graphite as matrix, through densification and graphitization treatment.

As an important member of the carbon fiber composite family, carbon carbon composites have many advantages of carbon and graphite materials, such as low density (theoretical density is less than 2.2 g/m³), high thermal conductivity [up to 400W/(m.k)], and low thermal expansion coefficient [(1-5)X10-6/℃]. Moreover, as a new structural material, carbon carbon composite materials have the characteristics of high specific strength, excellent thermal shock resistance, good ablation resistance, friction and wear resistance, and corrosion resistance. They can also withstand high temperatures above 3000 ℃. In particular, the unique property of carbon carbon composite materials that their strength increases instead of decreasing with increasing temperature makes them incomparable advantages in the selection of aircraft thermal protection systems and engine hot end components.

What is more, carbon carbon composite material, usually abbreviated as C/C or CFC.

CD Graphite Company’s CFC products have the best quality in China because we have the best scientific research team in China. Good quality and good service is our company’s advantage. We can solve customers’ confusions and problems by our technical team.

Carbon Carbon Composites Products

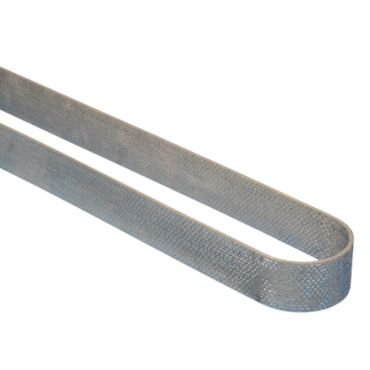

Composite fasteners composed entirely of carbon fibre-reinforced matrix are high-performance components for extreme environments. They withstand temperatures exceeding 2000°C in inert gases or vacuum, and endure prolonged exposure to 500–800°C in air. At elevated temperatures, their mechanical strength not only avoids the steep decline seen in metals but may even slightly increase due to graphitisation of the carbon fibres, whilst entirely avoiding metallic creep and melting issues.

Extremely low density (1.6–1.9 g/cm³), merely one-quarter that of steel and two-fifths that of titanium alloys, yet possessing exceptionally high strength and modulus, rendering it particularly suitable for applications where weight sensitivity is paramount.

An exceptionally low thermal expansion coefficient ensures carbon-carbon bolts and nuts maintain dimensional stability at elevated temperatures. When bonded to substrates such as ceramics or composites, they effectively mitigate thermal stresses, preventing loosening and failure caused by thermal expansion mismatch. Their favourable thermal conductivity facilitates uniform heat distribution, thereby averting localised overheating.

Highly resistant to most acids, alkalis, salts and solvents, making it suitable for corrosive environments. Its fibre-reinforced structure ensures extended fatigue life, eliminates metal creep issues at elevated temperatures, and delivers exceptional reliability. Maintains stable performance under nuclear radiation and high-energy ionising radiation conditions.

Self-lubricating properties are similar to graphite, with a low coefficient of friction, making it suitable for applications requiring maintenance-free lubrication.

The core advantage of carbon-carbon composite crucibles lies in their role as high-temperature-resistant, high-strength, long-life thermal field materials, making them particularly well-suited for the production requirements of large-size, high-quality monocrystalline silicon ingot pulling in the photovoltaic and semiconductor industries.

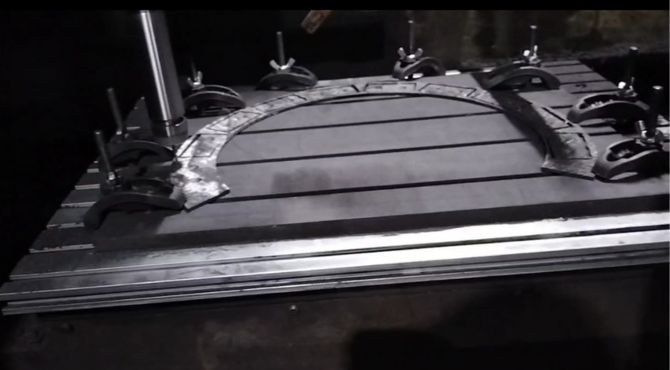

Prefab

From the dimension of manufacturing prefabricated body, there are 2D, 2.5D, 3D and other structures.

Chemical Vapor Deposition Electric Furnace

Operating temperature: 1500°C

Working area dimensions: φ600 × 800 mm

Graphitizing Electirc Furnace

Operating temperature: 2200°C

Working area dimensions: φ1700 × 2200 mm

Carbon Carbon Composites Parts Machining

- CFC Density Data Sheet

| C/C composites(CFC) | Directions of Fiber Structure | ||

| Type | 2D | 2.5D | 3D |

| Density (g/cm³) | 1.4-1.6 | 1.5-1.7 | 1.6-1.9 |

For more information, please do not hesitate to contact us.

Related Products

Compared to traditional materials such as steel and aluminium, carbon-carbon composites offer an exceptional strength-to-weight ratio, outstanding fatigue resistance, and excellent durability. These properties make them an ideal choice for achieving weight reduction while maintaining structural integrity.

The lightweight properties of carbon-carbon composites significantly reduce the overall weight of vehicles and aircraft. This weight reduction directly translates into enhanced fuel efficiency, reduced emissions, and increased payload capacity in aerospace applications.

Although the production of carbon-carbon composites requires substantial energy inputs, the long-term environmental benefits derived from reduced fuel consumption and extended service life often outweigh the initial impacts. Furthermore, emerging recycling technologies are progressively enhancing the sustainability of this material.