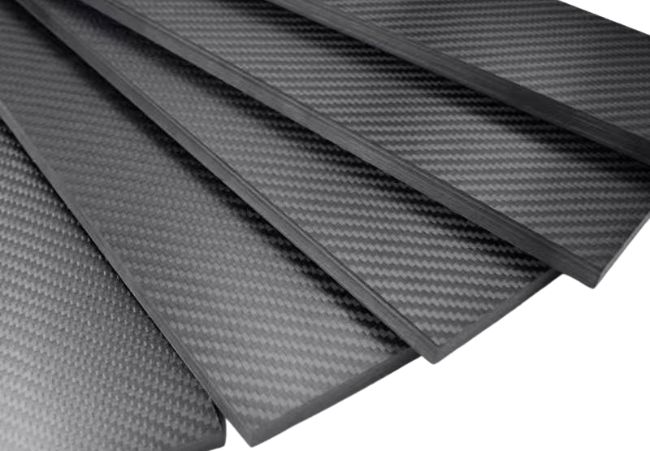

CFRP Tube and Plate

- Low Density

- High Strength

- Corrosion Resistant

- Fatigue resistant

- Excellent Mechanical Properties

- Wide Operating Temperature Range

- The exterior surface can be twill weave, plain weave, glossy, or matte.

What is CFRP?

CFRP is the abbreviation for carbon fiber reinforced plastic. It is a layered structure of carbon fiber and resin materials, a non-homogeneous material with excellent properties such as high specific modulus, high specific strength, corrosion resistance, and fatigue resistance. It is widely used in the aerospace and military industries. Its application ratio has become one of the important indicators for evaluating the advanced nature of aerospace aircraft and other products.

CFRP is currently the most widely used composite material.CFRP is a composite material composed of carbon fiber as the reinforcing phase and resin or carbon as the matrix.CFRP is a composite material composed of carbon fiber as the reinforcing phase and resin, ceramic, metal, cement, carbon, or rubber as the matrix. It has many advantages, such as high specific strength, high specific stiffness, good fatigue resistance, good overload resistance, strong corrosion resistance, and strong designability.

After considering the prices of various substrates and the processing costs of various processes, resin-based composite materials are currently the most widely used carbon fiber reinforced composite materials.CFRP has been around for decades but has not been widely used, not only because of its high price, but also because of its high processing costs and severe damage. However, the high processing costs and severe damage are caused by the composition and structural characteristics of CFRP.

CD Graphite Company has gradually overcome these problems by studying the thermodynamic properties of the various components that make up CFRP and the molding process of CFRP.

CFRP Products Overview

Autoclave Workshop

Prepreg Line Workshop

CNC Machining Center

CFRP Product Forming Methods

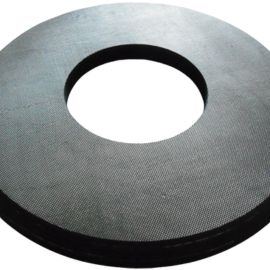

We have some forming methods for CFRP products. Winding Process-Filament Wound Product is one of them.

A precision engineered, machine made filament wound product, each individual carbon yarn is applied to a pre-set compute program with a unique angle to mandrel. The advantage of the winding process is the carbon fiber always can provide enough pre-loading as the fiber winding, to ensure all of them can be to share when the product have loaded.

Compression molding is a molding method in which intermediate base materials such as prepreg cloth are laid in a heated mold and then cured under pressure using a press.Since molds are used in the forming process, high-precision, high-quality parts can be obtained. At the same time, this method is highly efficient and suitable for mass production and high-strength parts manufacturing.