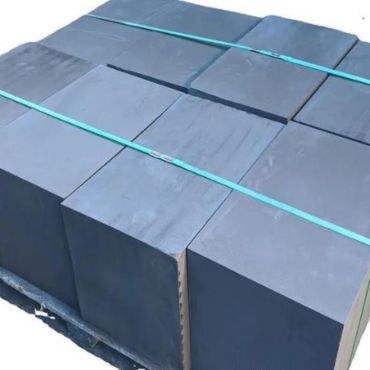

Graphite Block Ⅰ Isostatic Graphite

Isostatic Graphite made by CD Graphite has good quality and stable performance.Isostatic pressed graphite is called isostatic graphite, and its biggest characteristic is isotropy.Isostatic pressure forming is comp in the isostatic pressure vessel. The powder is placed into an elastic mold made of rubber or plastic, then sealed and put it into the high pressure container. With an ultra-high pressure pump, it is pressed by high pressure liquid medium (oil or water), so that the powder is pressed and formed. There are two kinds of isostatic forming: cold isostatic forming and hot isostatic forming.

- High Purity(C≥99.9%),

- High density (>1.73 g/cm³)

- High strength(flexural strength ≥ 40 Mpa)

- High Thermal Conductivity

- Low Thermal Expansion

- Good Electrical Conductivity

- Easy to machine

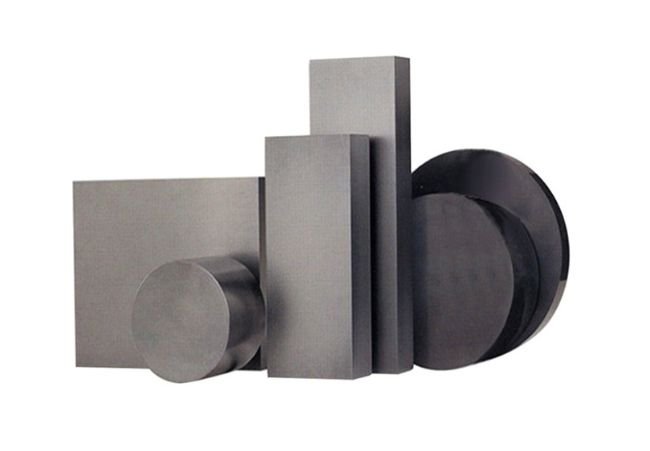

- Graphite Block , Plate and Rod

What is Graphite Block ?

Graphite block is the material for graphite machining products. It mainly has 4 types according to its moulding method, they are Isostatic Graphite(IG), Molded Graphite(MG),Vibrated Graphite(VG) and Extruded Graphite(EG).

We also called isostatic graphite(IG) and Molded Graphite(MG) High Purity Graphite, called Vibrated Graphite(VG) and Extruded Graphite(EG) Fine Grain Graphite.

4 Types of Graphite Block

Graphite Block Ⅱ Molded Graphite

Compared to isostatic graphite, Molded Graphite is an economical choice. The size of molded graphite is also smaller than isostatic graphite.

The molding method is suitable for pressing products with small size in three directions and small difference in size in three directions, structure densifed & uniform and high strength, but the product has anisotropy..

Graphite Block Ⅲ Vibrated Graphite

Vibration forming is to load the paste into the mold placed on the vibration table of the vibration forming machine, and then place a heavy hammer on it, and use the high-speed vibration of the vibration table to make the paste achieve the purpose of dense and formed.

Vibrated graphite is nearly the largest size dimension among the 4 types of materials. It could be more than 3m length and 2.3m diameter. It is Fine Grain Graphite, the grain size is 0.8mm and 2mm and more.

Graphite Block Ⅳ Extruded Graphite

Extruded Graphite only has rods and no blocks. It is also called Fine Grain Graphite, because its grain size is 0.8mm, 2mm even 4mm(some Graphite Electrodes).

The extrusion method is to use a horizontal extruder, load the paste into the press chamber, and add pressure to the paste with a plunger. Prepressing is performed first, and then pressure is applied to squeeze the paste out of the nozzle, and cut itoff according to the required length, then the blank is made.

Extrusion method has high production efficiency, simple operation and high degree of mechanization. However, the product has low density and low mechanical strength. The products can be used to produce graphite electrodes, graphite rotors and graphite crucible and so on.

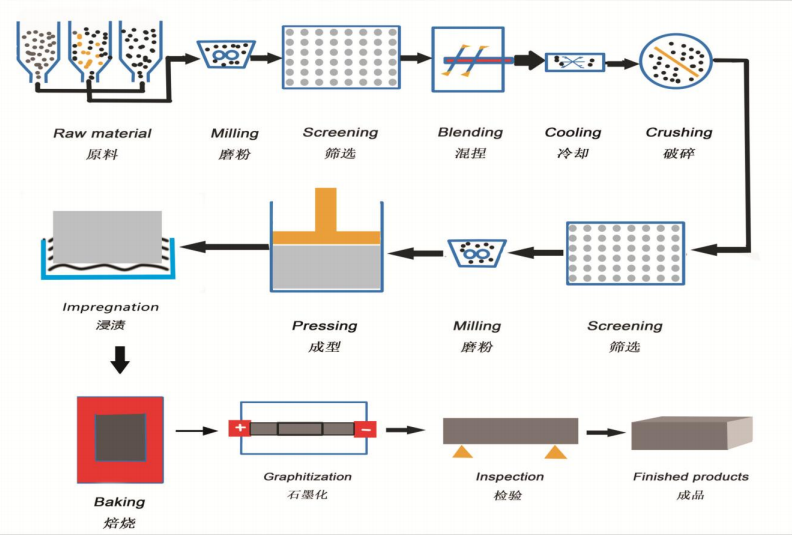

The Flow Chart of Fine Structure Graphite

CD Graphite is a professional manufacturer of fine graphite series products. We have 3000 tons double sides compressor, isostatic pressing machine and other advanced equipments. There is a high-tech production line which can produce 10000 tons big size fine structure isostatic high purity graphite each year.