Carbon Fiber Fabric of CD Graphite Company

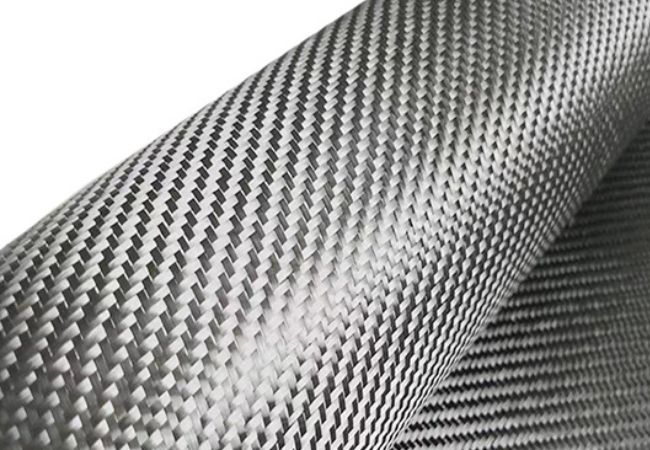

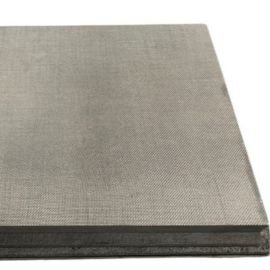

Our company’s carbon fiber fabric mainly include various specifications and models(1k, 3k, 6k, 12k, 24k, 50k) of carbon fiber woven cloth, axial cloth, pre-preg cloth, carbon fiber fort cut, carbon fiber modified plastic and other carbon fiber materials.

- Unidirectional carbon fiber fabric

- Bi-directional carbon fiber fabric

- Carbon fiber prepreg fabric

- Aramid fiber fabric

- Hybrid fabric

- Multi-axial fabric

All Kinds of Carbon Fiber Fabric

It is weaved by 1k, 3k, 6k, 12k, 24k carbon fiber. The weave pattern are plain, tiwll and satin and so on. We also have gitter carbon fabric, jacquard carbon fabric, hybrid fabric with other high performance fibers(aramid, UHMWPE, basalt, fiber textile tape, textile braid and 3D textile).

Production Equipment 1

Pre-impregnating Equipment

Production Equipment 2

Weaving Loom

Production Equipment 3

Pre-impregnated Yarn Shelf

Related Products

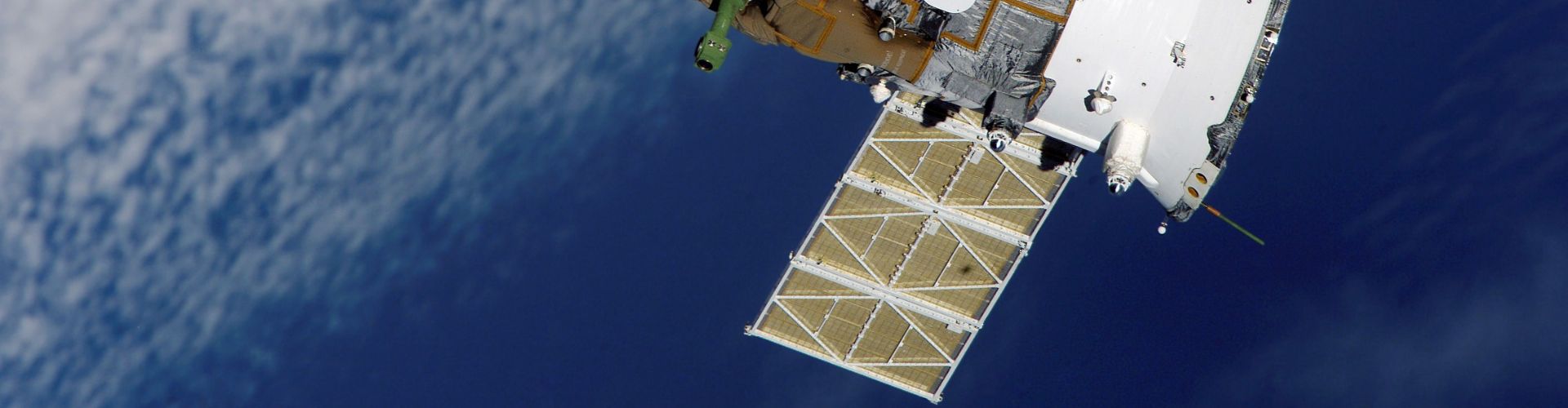

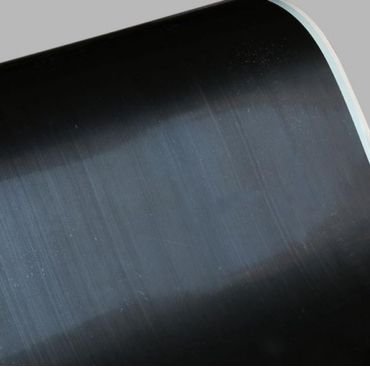

Industrial-grade carbon fibre fabrics exhibit exceptional resistance to environmental factors, including ultraviolet radiation, extreme temperatures, and humidity. This material maintains its structural integrity and performance characteristics under diverse weather conditions, rendering it suitable for outdoor applications. However, for specific environmental exposures, the application of appropriate coatings and protective systems is recommended.

Compared to conventional materials, this material typically requires minimal maintenance. Regular visual inspections are recommended to identify any damage or wear, though its inherent durability and corrosion resistance eliminate many routine maintenance requirements. Where necessary, maintenance should be carried out by qualified technicians in accordance with the manufacturer’s specifications.

Under standardised design and correct installation conditions, industrial-grade carbon fibre fabrics can retain their performance characteristics for decades. Actual service life depends on the application environment and exposure conditions, but most installations exhibit only minor degradation over 20 to 30 years. This long-term durability significantly enhances the material’s overall value proposition and return on investment.