Graphite deposits are mined using conventional minging methods. Flake graphite deposits are typically found near the surface and depending on the degree of weathering, can be mined using conventional hard or soft-rock mining techniques. Amorphous graphite deposits are exploited using conventional coal-type extraction techniques, while vein graphite deposits can be mined using openpit or conventional shaft methods. While flake and amorphous graphite deposits are currently mined in both underground and open pit operations, vein graphite deposits are almost exclusively mined in underground operations.

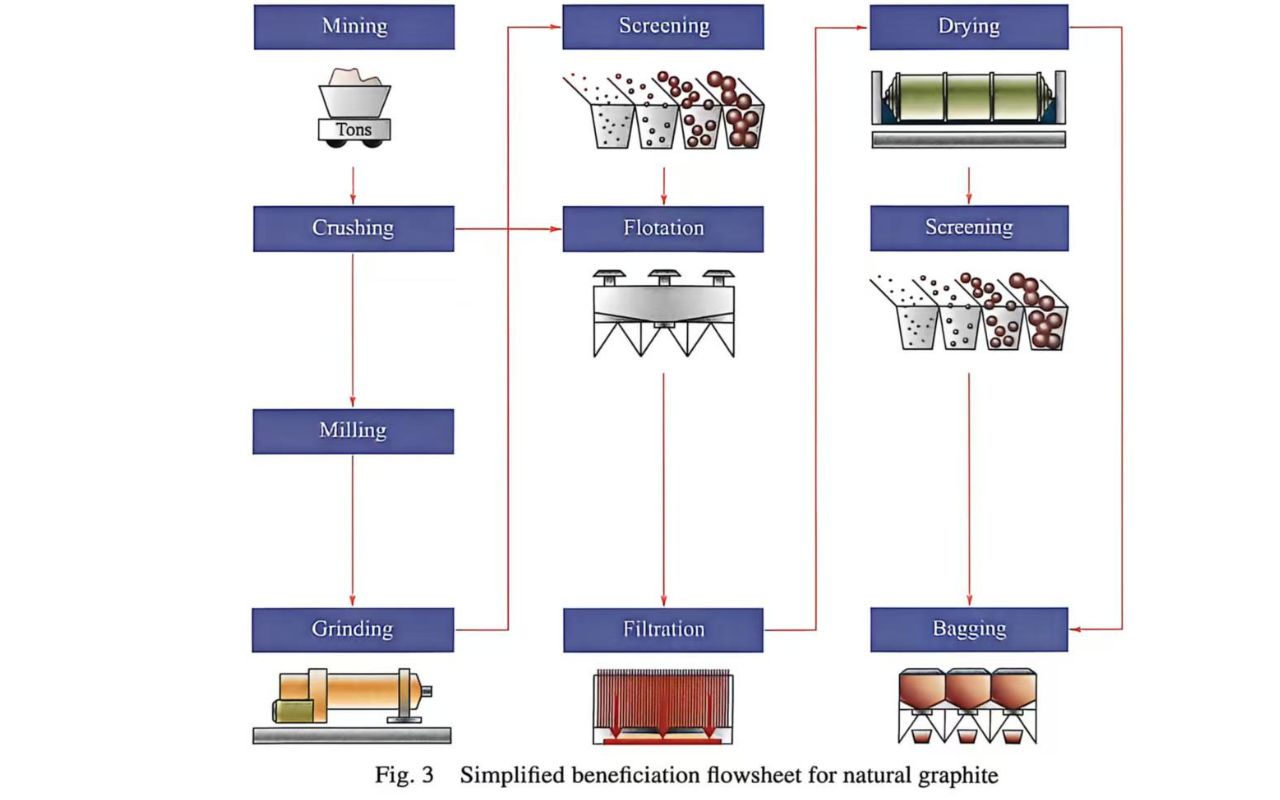

Beneficiation techniques depend on the type of deposit, flake size distribution, and the required specifications of the final concentrate such as crystallinity, texture of the flakes, ash content and level of impurities. They can be divided into comminution, neneficiation and for flake graphite, refining stages. Commimution process focus on the liberation of graphite flakes from the host rock to increase recovery during the following beneficiation stages. The liberation of the graphite flakes is critical for the ultimate grade of the final product. However, as flake size and carbon content are important commercial considerations, with large and jumbo graphite flakes commanding the highest prices, any processing that reduces flake size should be kept to a minimum. Depending on the type of graphite ore, processing flowsheets for the comminution stage can vary greatly. A simplified natural graphite beneficiation flowsheet is shown in Figure3. A combination of crushing and grinding techniques using ball mills, hammer mills, air jet mills and rod mills maybe employed, with a number of screening stages to maximise recovery of large flakes. Attrition scrubbing processes to remove impurities while preserving crystallinity of the graphite flake may follow milling and grinding.

Following mechanical liberation of the graphite flakes from the enclosing country rock, a range of further purification techniques can be employed to remove impurities, for instance, hydrometallurgical(froth flotation, gravity separation, acid base and hydrofluoric acid methods) and pyrometallurgical methods(chlorination roasting and high-temperature methods). As graphite is nattrally hydrophobic, the most widely used graphite beneficiation technique is forth flotation, and graphite was, in fact, the first ore mineral to be concentrated by flotation in 1877. Ore slurry is fed into froth flotation cells abd mixed with water and flotation agents, resulting in the flotation agents sticking to the graphite flakes. As air is injected into the cell, the graphite flakes stick to the are bubbles and float to the top of the cell where they are skimmed off. Flotation flowsheets very depending on the ore ttpe, and may include conventional and column flotation. They typically include a rougher flotation step with several stages of cleaning.

Flake and vein graphite deposits generally have a higher carbon content and purity. Crystallinity, the surface area and the texture of the flakes, as well as the ash content and level of impurity can all be controlled to a certain point during these processing stages. A repetition of the crushing and grinding processing steps and the refloating of flotation-beneficiated flakes may progressively increase purity. Grades of typically 95%-97% and up to 99% carbon can thus be achieved for flake and vein graphite concentrates. Amorphous graphite deposits generally have a higher ash content, with impurities attached to the graphite crystals or contained within the lattice structure. This makes flotation and other chemical-based separation techniques in these types of deposits difficult, and the concentrate grades obtained at 75-85% are generally substantially lower. Yield rates depend on the processing technology and efficiency and can vary greatly across the different producer countries. Chinese yield rates are typpically assumed to be in the 50%-55% range, while Indian yield rates as low as 20% of crude output.

Following the flotation stage, the concentrate is filtered and dried before being bagged for transport. The product may also undergo screening into different fractions.

High-end applications, such as battery applications, flame retardants and graphite gaskets and seals require upgrading to purities in excess of 99% carbon. Mineral grain impurities attached to the surface of the graphite flake itself, trapped between adjacent flakes or intercalated between the graphene layers of the graphite crystal cannot be removed using mechanical methods and usually require thermal or chemical treatment. Further processing depends on the level of contaminants in the deposits and its physical characteristics such as particle size, as well as on customer requirements and the application of the end product. Chemical purification technique can yield grades of 99.8% and include the use of strong acids such as HF, HCL, H₂SO₄,HNO3,raising concerns over environmental pollution. Thermal purification requiring large amounts of energy to heat graphite to temperatures of up to 3000℃ can achieve grades exceeding 99.99%. The use of strong acid and reagents and high production and energy costs have thus far discouraged any commercially viable development of processing capacity worth mentioning outside China. The lithium-ion manufacturing value chain in particular is currently almost exclusively focused on China, with some high-end processing in the Republic of Korea and Japan.