Graphite is lightweight, naturally soft and exhibits physical and chemical properties of both metals and non-metals, making it ideally suited for a range of industrial and technological applications. The metal properties of graphite include high thermal and electrical conductivity, while inertness and high resistance in chemical and corrosive applications, high heat resistance and excellent cleavage. And lubricity are non-metal characteristics. With a melting point of 3850+-50℃, graphite is used in applications requiring a high temperature environment. Although flake and amorphous graphite compete across a range of applications to a point, the the ultimate choice of material is often down to cost and performance considerations.

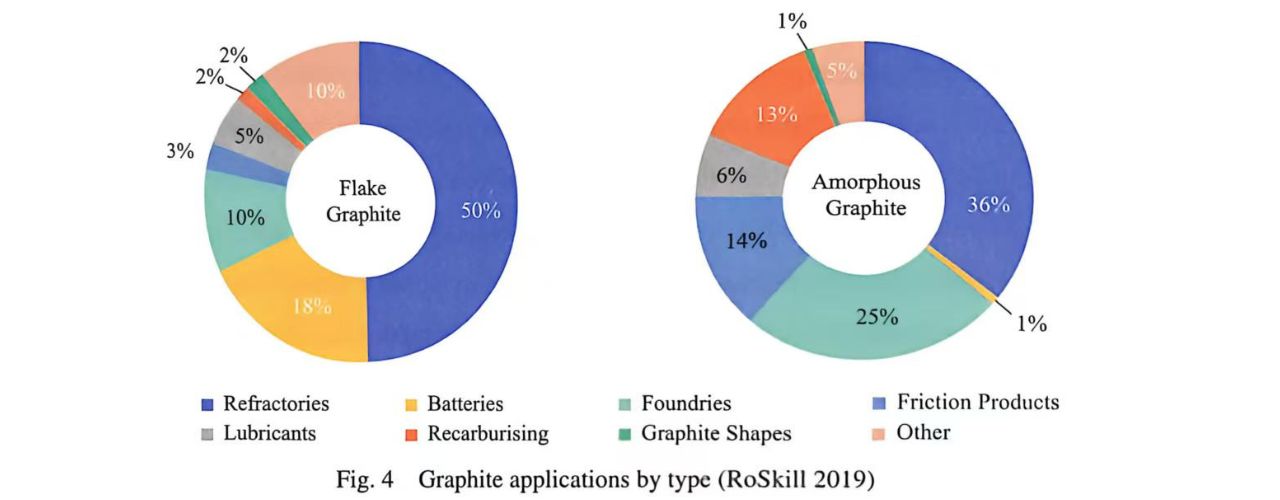

The refractory industry continues to be the largest market for both types of natural graphite where it is used in the production of materials for high-temperature environment such as the linings for kilns, incinerators, reactors and furnaces. Predominantly large flakes are used in the production of refractory materials, with some smaller flake sizes and amorphous graphite also used. The steel industry is by far the largest consumer of refractory materials, followed by the non-ferrous metals and non-metallic producing industries such as cement and glass production. In refractories, graphite is used in the form of magnesia-carbon, alumina-carbon, alumina-magnesia-carbon and silicon carbide-graphite, and as graphite blocks in electric arc and basic oxygen furnaces, linings in ilmenite smelting and crucibles in steel, non-ferrous and precious metal production.

The foundry industry accounted for the third largest application of flake and the second largest application of amorphous graphite, with use as facing sand and mould wash in a variety of casting methods. The production of ferrous castings had the largest global share of all casting methods, followed by non-ferrous casting such as aluminium, copper,zinc and lead, magnesium and titanium-based casting. The main applications for foundry-cast metals include the automotive and other transport industries, pipelines and machinery.

Graphite is the most widely used anode material in batteries. Battery types include both primary(non-rechargeable) and secondary(rechargeable) batteries, where natural graphite competes with synthetic graphite across a range of different battery types. In 2018, approximately 14% of natural graphite worldwide was in batteries(RoSkill 2015). Close to 90% of all natural graphite consumption in batteries was in lithium-ion batteries, with the balance consumed in primary batteries(such as alkaline and zincair), as well as other secondary batteries(such as lead-acid and nickel-metal-hydride).

Other applications for both flake and amorphous graphite include lubricants such as oils, greases and fluid dispersion in industrial and consumer applications; shaped graphite products for the automotive, aerospace, eletronics and industrial machinery industries; friction materials such as used in brake pads and clutches in the automotive and aviation industries; and in the construction industry and other specialty applications.