Within the vast realm of materials science, carbon fibre stands out with its unique allure, becoming the darling of numerous fields. But do you truly understand it? Today, we delve deep into carbon fibre, discussing what the K number signifies, the meaning behind T300 and T700, and the application domains of different grades like 25T and 40T.

What does the K number signify? The thickness of carbon fibre

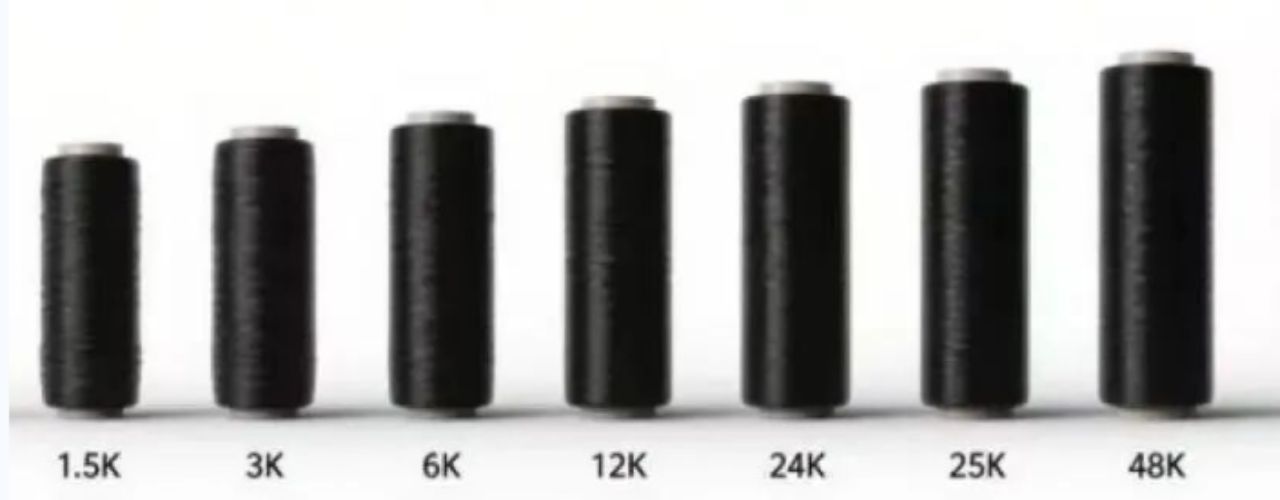

The ‘K number’ denotes the quantity of individual filaments within a carbon fibre towing, specifically ‘thousand filaments’ (e.g., 1K = 1,000 filaments, 3K = 3,000 filaments). Here, “K” is an abbreviation for the English ‘kilo’ (thousand). Common carbon fibre tows include 1K, 1.5K, 3K, 6K, 12K, 24K, 25K, 48K, and 50K.

1K, 1.5K

Extremely fine carbon fibres, lightweight yet costly, suited for high-precision weaving (e.g., premium bicycles, fishing rods).

3K, 6K, 12K

Medium thickness. 3K is the most popular and widely used variant on the market. It is lightweight, relatively strong, easy to process and manufacture, and imparts a classic carbon fibre appearance to products. Widely used in sporting goods (e.g., golf clubs, tennis rackets) and drone components.

24K, 48K, 50K

Coarse filament bundles. Lower cost, predominantly used in industrial applications (e.g., automotive structural components, wind turbine blades).

What do T300 to T1100 signify? Strength grades of carbon fibre

In the realm of carbon fibre, the letter “T” serves as a measure of strength, with the following number indicating its ranking within the “strength tier” (measured in MPa). The higher the number, the greater the tensile strength, and the more force it can withstand.

| Grade | Tensile strength MPa | Elastic

modulus GPa |

Elongation at break % | Density g/cm³ | Key features | Applications |

| T300 | 4000 | 230 | 1.5 | 1.76 | Universal type, Low-cost | Fishing rods, golf clubs, industrial components |

| T400 | 4300-4500 | 250 | 1.7 | 1.8 | Strength superior to T300, a mid-range option | Drone frames, bicycle frames, automotive components |

| T700 | 4900 | 240 | 2 | 1.8 | High strength, Excellent overall performance | Aircraft sub-structures, high-pressure gas cylinders, supercar bodies |

| T1100 | 7000 | 320 | 2.2 | 1.8 | Ultra-high strength, High modulus, Cutting-edge materials | Spacecraft primary structure, fighter aircraft components, missiles |

What are 24T to 40T? Carbon fibre modulus grades

Definition of modulus

Modulus (Elastic Modulus) denotes a material’s resistance to deformation, measured in GPa (gigapascals).

Higher modulus indicates greater rigidity and reduced deformation under stress.

High-modulus carbon fibre features exceptional stiffness, low thermal expansion coefficient, and lightweight properties, though it exhibits greater brittleness.

Meaning of the 24T, 30T, 36T, 40T Grades

The numerical values in these designations represent approximate modulus values (in GPa), for example:

24T ≈ 240 GPa

30T ≈ 300 GPa

36T ≈ 360 GPa

40T ≈ 400 GPa

| Grade | Tensile strength GPa | Elastic

modulus GPa |

Density g/cm³ | Key features |

| 24T | 4 | 240 | 1.81 | Entry-level, Highly cost-effective |

| 30T | 4.5 | 300 | 1.82 | Medium-high modulus,High overall cost-effectiveness |

| 36T | 5 | 360 | 1.84 | High modulus |

| 40T | 5.5 | 400 | 1.85 | Top modulus |

Note: Specifications may vary slightly between different brands.

Application scenarios for different modulus grades

| Grade | Applications | Representative products |

| 24T | High-end sports equipment, automotive lightweighting | Rowing oar blades, supercar body panels |

| 30T | Aviation sub-assemblies,UAV airframes | Drone main spar,Helicopter rotor blade |

| 36T | Spacecraft primary structure,Missile casing | Satellite mount,Rocket fuel tank |

| 40T | Top-tier aerospace and defence precision components | Space telescope mirror assembly,Intercontinental ballistic missile conical warhead |

Case Study

(1) The mirror support structure of the James Webb Space Telescope employs 40T-grade carbon fibre, ensuring zero deformation at -270°C in deep space.

(2) Intercontinental ballistic missile warheads must withstand extreme temperatures and impacts during atmospheric re-entry; 40T carbon fibre ranks among the few materials capable of meeting these demands.

High-Modulus Carbon Fibre: Pushing the Boundaries of Human Technology

From 24T to 40T, each incremental advancement pushes the modulus of carbon fibre beyond the limits of materials science. It is precisely these cutting-edge materials – rigid as iron yet light as a feather – that enable satellites to pinpoint locations, fighter jets to soar through the skies, and telescopes to peer into the farthest reaches of the cosmos.