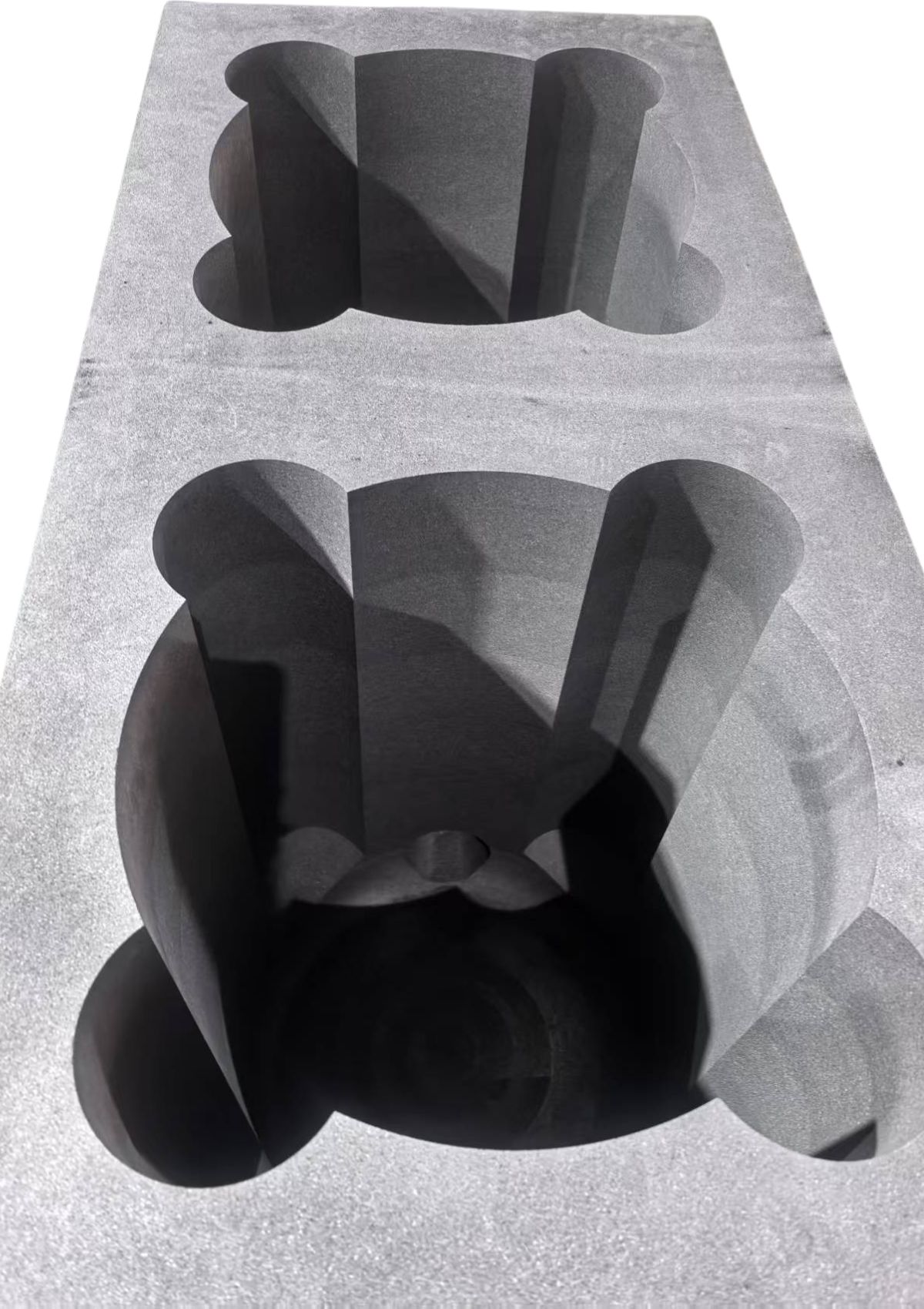

Many Kinds of Graphite Crucibles from CD Graphite Company

Graphite crucibles offer significant advantages in high-temperature and chemically aggressive environments due to their unique material properties, and the following are key benefits of graphite crucibles from CD Graphite Company.

1 Excellent high temperature resistance – high temperature stability and thermal shock resistance;

2 High thermal conductivity and thermal conductivity – fast thermal conductivity and energy saving effect;

3 Chemical Resistance – Resistant to molten metal corrosion and acids and alkalis;

4 Mechanical strength and durability – high high temperature strength and long service life;

5 Lightweight and easy to machine – light weight versus metal crucibles, customizable;

6 Economical – cost-effective and less polluting;

7 High purity – ash less than 5ppm.

- Graphite Crucible Processing Capability of CD Graphite

Different industries have different requirements for the use of graphite crucibles and different emphasis on crucibles.

For example, metallurgy and foundry focus on resistance to metal erosion and thermal shock; semiconductor and photovoltaic require ultra-high purity, low impurities, and very high processing precision; chemical industry requires resistance to acid and alkali corrosion, and graphite crucibles may also need to be coated.

CD Graphite Company is good at making graphite crucibles used in various different industries because we have a team specialized in making graphite crucibles. We will choose the right graphite material according to the customer’s usage needs, whether to use isostatic graphite or vibrated graphite or extruded graphite; whether the graphite crucible needs to be coated or not, which kind of coated material do customers’ need, and whether it needs to be high purity or not. We all can make them right.

We also have a full set of processing equipments in order to meet the needs of our customers, regardless of the size of graphite crucibles. We can guarantee the dimensional accuracy of small size crucibles down to +-0.01mm; graphite crucibles for gold melting require high purity and are polished to a mirror finish. Large size graphite crucible can be φ600X1100mm, 200X 400X 3000mm and so on.

CD Graphite Company’s mechanics are very experienced in machining, and many of the veteran mechanics have been in the industry for decades, which also saves customers money on production costs.

By all accounts, if you need graphite crucibles, graphite crucibles from CD Graphite Company are your best choice.

Graphite Crucible Application Industries

1 Semiconductor industry: monocrystalline silicon production and silicon carbide crystal growth require graphite crucibles to withstand high temperatures of over 1500°C and extreme thermal shock.

2 Photovoltaic industry: polysilicon ingot casting, requiring graphite crucibles of high purity and thermal shock resistance.

3 Metal metallurgy: rare metal purification, high temperature alloy making.

4 Nuclear industry: reactor components.

5 Glass industry and powder metallurgy, etc.